Our Quality Policy is to become the Market leader in the Supply of piping products while maintaining the integrity of purpose with customers and employees alike.Also included in our policy is to:

Gips adopts an international practice of implementing and adhering to a quality assurance system (i.e. process based approach) & has been certified to ISO-9001: 2015. Moreover, periodic checks are put in place to ensure the system is adhered to line with the latest quality trends, emphasizing on customer needs & customer satisfaction at relevant levels. Gips always looks forward in enhancing customer satisfaction by value added services and continual improvement.

We also provide technical documentation and final data dossiers in the contractual language to complete the supply. Documentation supply depending on client request may consist of:

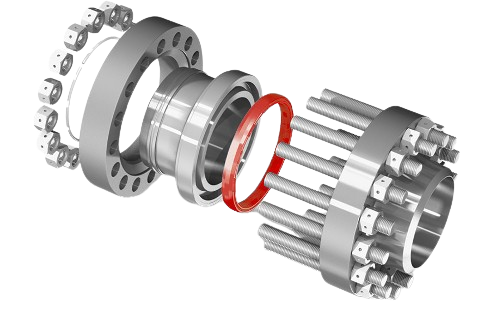

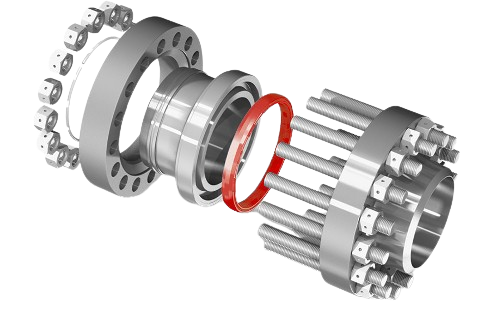

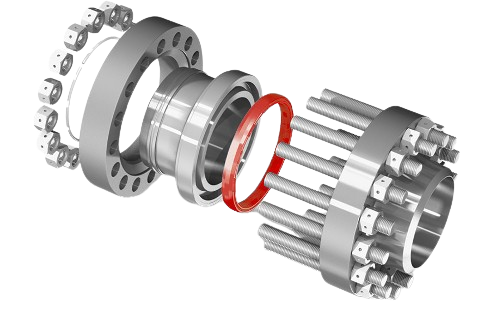

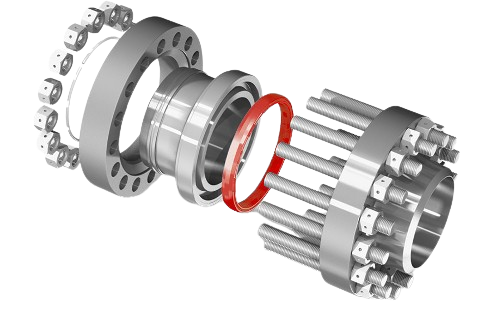

No matter where you are or what your piping need, we work together to deliver exceptional performance. As an ISO 9001:2008 certified company, we adhere to the latest quality standards with a core emphasis to customer needs and satisfaction. Our products meet all international standards, such as ISO, API & ASME are ably supported by an efficient procurement and project management team that is in constant touch with partnered manufacturers to provide the finest product choices at the most competitive price.

We are approved in all the oil majors, such as, SAUDI ARAMCO (and its affiliates), SHELL, ADNOC, GASCO, SABIC, Petroleum Development of Oman (PDO), Kuwait Oil Company (KOC), KNPC, Saudi Electric Company (SEC), MARAFIQ, and many more. Gips Piping has maintained its position as a preferred choice by all the major EPCs and End Users from around the world with our supply portfolio spanning across six continents.

Gips has established a system which ensures the final product is in line with the customer requirements. All the stages that affect product quality are fully monitored and controlled by equipped competent personnel. Gips believes in professionalism when approaching customer needs. Care has been taken to ensure our clientele get value added services including, but not limited to, technical documentation/records/material testing as part of relevant material specification or special requirements.

With our collaboration with qualified laboratories we can perform any of the following tests on our supplied material when required by Project specifications:

Our Quality Policy is to become the Market leader in the Supply of piping products while maintaining the integrity of purpose with customers and employees alike.Also included in our policy is to:

Gips adopts an international practice of implementing and adhering to a quality assurance system (i.e. process based approach) & has been certified to ISO-9001: 2015. Moreover, periodic checks are put in place to ensure the system is adhered to line with the latest quality trends, emphasizing on customer needs & customer satisfaction at relevant levels. Gips always looks forward in enhancing customer satisfaction by value added services and continual improvement.

We also provide technical documentation and final data dossiers in the contractual language to complete the supply. Documentation supply depending on client request may consist of:

No matter where you are or what your piping need, we work together to deliver exceptional performance. As an ISO 9001:2008 certified company, we adhere to the latest quality standards with a core emphasis to customer needs and satisfaction. Our products meet all international standards, such as ISO, API & ASME are ably supported by an efficient procurement and project management team that is in constant touch with partnered manufacturers to provide the finest product choices at the most competitive price.

We are approved in all the oil majors, such as, SAUDI ARAMCO (and its affiliates), SHELL, ADNOC, GASCO, SABIC, Petroleum Development of Oman (PDO), Kuwait Oil Company (KOC), KNPC, Saudi Electric Company (SEC), MARAFIQ, and many more. Gips Piping has maintained its position as a preferred choice by all the major EPCs and End Users from around the world with our supply portfolio spanning across six continents.

Gips has established a system which ensures the final product is in line with the customer requirements. All the stages that affect product quality are fully monitored and controlled by equipped competent personnel. Gips believes in professionalism when approaching customer needs. Care has been taken to ensure our clientele get value added services including, but not limited to, technical documentation/records/material testing as part of relevant material specification or special requirements.

With our collaboration with qualified laboratories we can perform any of the following tests on our supplied material when required by Project specifications:

Years of Experience

Project Completed

Satisfaction Rate

Global Industrial Piping solution (GIPS) - a specialist global supplier of world class piping products together with turn-key services & solutions, project supply management and consultancy to the leading names.

Mon - Sat: 8 am - 5 pm, Sunday: CLOSED

Copyright ©2023 GIPS Group Designed By MetaUX.